RIGGING QUIZ No. 26

GIVEN:

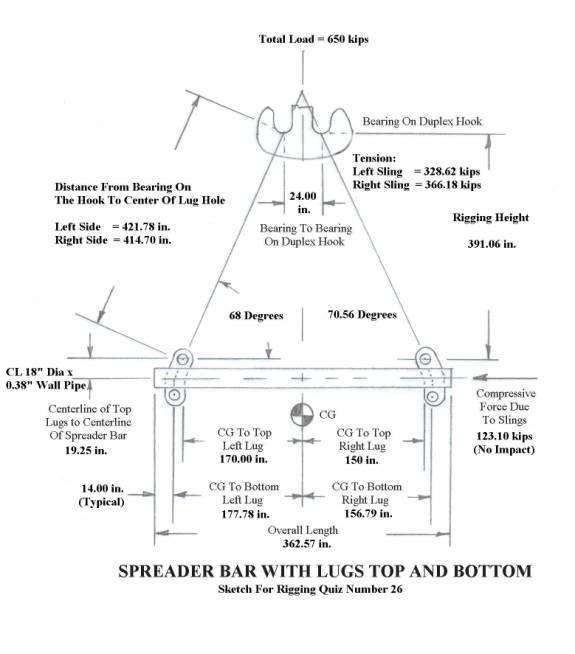

1. The sketch of a pipe spreader bar

2. Design information not shown on the sketch

a. Tension in the left vertical sling below the spreader bar = 304.63 kips

b. Tension in the right vertical sling below the spreader bar = 345.37 kips

c. Fy = 36 ksi

d. Impact factor = 1.8

e. Each prong of the duplex hook is 8” in diameter

f. The vertical height from the centerline of the spreader bar down to the center of the lifting lug holes on the vessel is 180.00 in.

3. The rigging hook up for each side above the spreader is per the sketch, ie an inclined sling over the hook and connected to a top lug with a shackle

4. The rigging hook up for each side below the spreader is a vertical sling connected to a bottom lug on the spreader bar with a shackle and connected to the lug on the vessel with a shackle

5. The information on the sketch was obtained from the spreader bar program with lugs top and bottom (English version) in the design section of this website. To see the complete input/output information, open the program, click on the sample values and then input the information off the sketch. Leave the properties for a 18” x 0.375 pipe as is. Calculate and note that with this configuration there is very little bending due to the influence of the slings. Also note that the combined stress check is 0.72, a very nice safety factor

6. The 19.25 in. for the vertical distance from the centerline of the top lug holes down to the centerline of the spreader bar was used to allow ample room for pads, pad welds and the lug welds

FIND:

1. Design lifting lugs for the above spreader bar to carry a 650 kip load

a. Feel free to use the pad eye lug design program in the design section of this website

b. Use the same design criteria as in the pad eye lug program, ie, Fy = 36 ksi, impact factor = 1.8, allowable force on the weld = 14.85 kips/in, etc.

2. Make a detail drawing of the lifting lugs showing their shape and how they will be attached to the pipe spreader bar, ie butt welds, fillet welds, etc. Include weld sizes

3. Use the same shackle size for all four lugs on the spreader bar and for both lifting lugs on the vessel

4. Select a sling for the right side above the spreader bar. Use this same size of sling for the other three slings. Feel free to use the program that calculates the safe working load of a sling when bent over a hook, the bail of a shackle, etc, located in the design section of this website

5. Calculate the total length of the four slings required

Maximum Reach Enterprises