HELP

FILE FOR: PROGRAM FOR SOLVING THE

SAFE WORKING LOAD FOR A SLING BENT AROUND A PIN, SHEAVE, ETC.

DEFINITION:

Testing by Macwhyte has shown that if a sling is bent around or over a pin, over a hook, around a sheave, etc., then a reduction in the safe working load (SWL) for the sling in a straight pull must be taken. See the sketch below for an example of a sling bent around a pin.

PROGRAM OBJECTIVE:

The objective of this program is to solve for the SWL for a sling that is bent around a pin, over a hook, etc. There are two methods to calculate the SWL.

1. Start with the SWL of a wire rope at 100 % efficiency, ie where the breaking strength of the wire rope is divided by a safety factor of 5. Then figure the efficiency factor reductions due to end attachments at the eye of the sling, the sling being bent around a curved end plate of a spreader bar, around trunnions, around shackle pins, etc. Then select the efficiency factor that will cause the greatest reduction in strength and multiply it by the SWL of the wire rope.

For example, if the SWL of the wire rope is 100 kips, the efficiency factor for the end attachment is 90%, for the curved plate 82% and the trunnion 89%, then the worst case would be for the curved plate. The SWL for the sling would be 100 kips*.82 = 82 kips. Note that only the worst-case efficiency factor is used as the reductions do not all occur at the same place on the sling.

2. The user could start with the SWL of a sling taken off a sling chart. The SWL in this case already includes a reduction factor for the end attachment at the eye of the sling. The user would then calculate the other efficiency factors as shown above and multiply the worst case by the SWL of the sling. This would yield the adjusted SWL of the sling.

There is nothing wrong with this method as it yields a higher factor of safety, but in some cases the user is penalized by having to go to a larger size sling to handle the load, which he might not have had to do if he had analyzed it according to the first method.

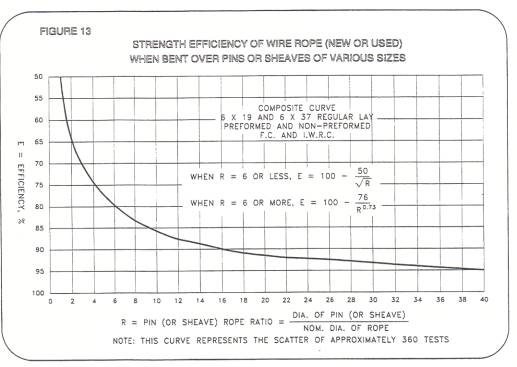

The program uses Macwhyte’s formulas to solve for the efficiency factors that must be taken due to bending the sling around pins, etc. See the graph at the end of this file for the formulas.

See the example at the bottom of the file

UNITS:

Input can be either English or Metric. Output will be in the same units as the input. The program has been written such that unit conversions are not necessary. Enter the input in the units desired and click the radio button for these units. This will ensure that the printout will show what units were actually used in the calculations for later reference.

END ATTACHMENT FACTORS:

A loss in sling strength due to end attachment factors must be taken for all slings, unless the SWL of the sling is from a sling chart as explained above. This reduction is approximately 90% but the user should use the following table to get the correct reduction for the type of sling being used.

Most manufactured slings fall under the category of “Mechanical Splice”.

See the efficiency factors in the table below.

WIRE ROPE DATA:

The SWL of wire rope at 100% efficiency is given in the table below. To determine the SWL of a sling, a value from this table must be multiplied by the efficiency factor for the end attachment at the eye of the sling, the efficiency factor for bending around a trunnion, etc. As stated above, only the efficiency factor that results in the largest reduction in SWL of the wire rope should be used.

The wire rope data table below is for USA wire rope. For properties of wire rope made in Europe or Asia, the user will have to refer to other sources.

EXAMPLE 1:

The “sample values” button in the program contains input where a 2” (50 mm) EIPS sling is bent around the curved end plate of a spreader bar with a 15” (381 mm) diameter and around a 30” (762 mm) diameter trunnion. Note that the efficiency factors for the end attachment is 90%, the curved plate of the spreader bar is 82.54% and the trunnion is 89.47%. The 82.54% was used in reducing the SWL of the wire rope to arrive at the SWL of the sling, ie, 79.2 kips * 0.825 * 2 parts = 130.74 kips which is greater than the maximum tension of 125 kips.

In the above example, no reduction for the eyes of the sling over the hook is necessary because there are two parts to the eye. If the diameter of the hook is say 4” (100 mm”), then the hook/sling ratio would be 2 and the efficiency factor would be 64.64 %. The SWL of the eye of the sling is then 79.2*0.64*2 = 101.38 kips, which is greater than the 79.2 kips of the body of the sling. In general, as long as the efficiency factor of the eyes is 50 % or greater, the eyes are as strong or stronger than the body. An exception to this would be when the eyes of a sling are over a hook and the eyes are very small compared to diameter of the hook. The wire rope in the eyes next to the crotch would be at a very extreme angle and have very high tension. Each part could have way more than 50 % of the load carried by the sling. Not only could both parts of the eye be over loaded in this case, but also they would be in extreme bending where they come out of the swage fitting. That is where they would break, or the swage fitting would break. Therefore, specify very large eyes when ordering new slings.

An example where the efficiency factor of the eye might be less than 50 % would be when the eye is over a small shackle pin. If the shackle pin is 1.75” (45 mm) and the sling diameter is 2” (50 mm), then the efficiency factor would be 46.55 %. Now the SWL of the eye would be 79.2*46*2 = 72.86 kips. In this case, the shackle pin would be acting pretty much like a knife and would be trying to cut through the end of the eye. Always use a pin diameter as large or larger than the sling diameter.

The units of example 1 are in kips and inches.

MacWhyte’s Graph for efficiency factor E is shown below:

END OF HELP FILE