Question 1:

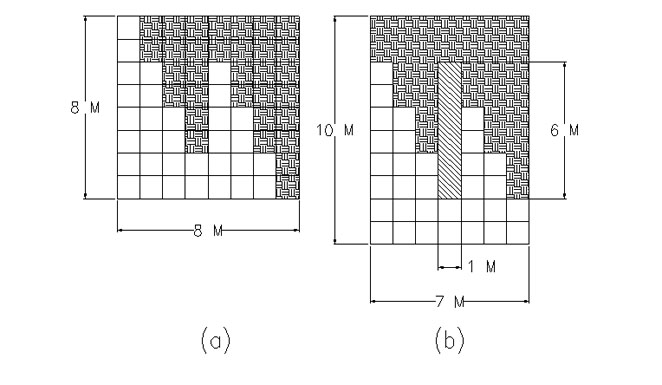

Cut the 8 m x 8 m plate in two pieces as shown in Figure-a. Move the crosshatched piece (the one on the right side) up and lap it over the left piece so that a total width of both pieces is 7 m and a total height is 10 m. See Figure-b.

Place the 1 m x 6 m piece of plate in the void between the two big pieces of plate. Weld the three pieces of plate together.

Question 2:

One easy way to check the corner of two walls for square is to use a 3 --4 --5 triangle relationship. Using a measuring tape, the carpenter starts at the inside corner of the wall and measures a distance of 3 along one wall and makes a point A. He then measures from the corner a distance of 4 along the other wall and makes a point B. He then measures diagonally from point A to point B. If the measurement is 5, then the two walls have a square corner. The carpenter can use any multiples of the 3--4---5 triangle, for example, he can use 30 to point A and 40 to point B. The diagonal distance between points A & B would then be 50 for the two walls to have a square corner.

Question 3:

a. When the bucket is empty, the soil loading under the front tires is approximately 55 psi.

b. When the bucket is full, the soil loading under the front tires is approximately 55 psi.

The approximate soil loading under the front loader tires is 55 psi in both cases above because:

When the bucket is empty, the width of the foot print under each front tire bearing on the ground is somewhat less than the width of the tire and the length of the foot print is very small, making the foot print a narrow band. By dividing the load exerted on the ground from a front tire by the area of the footprint, the soil bearing pressure will be approximately 55 psi.

When the bucket is full, the additional weight flattens out the front tires, so that now the width of the foot print under each front tire bearing on the ground is a little wider but quite a bit longer, making the foot print a rectangle. Again, by dividing the load to the ground from the front tire by the area of the footprint, the soil bearing pressure will still be approximately 55 psi.

The 55 psi under the front loader tires is equal to 7,900 psf. On most of our construction projects, an average allowable soil bearing pressure is about 4,000 psf. If you followed this loader around on 4,000 psf soil, you would notice it leaving tire tracks as it is over loading the soil and the tires sink into the soil until they pick up a bearing area that equals 8,000 psf. This is usually not a problem, unless the loader is running on asphalt, because we dont care if some settlements of the tires occur.

A loaded 10 wheeler dump truck with a tire pressure of 75 psi has a soil loading of about 10,800 psf, which is generally much higher than the loading to the soil from most heavy lifts. Running it along the haul route or over the crane pad is a good way to do some compaction and find any soft spots.

Maximum Reach Enterprises