FIND:

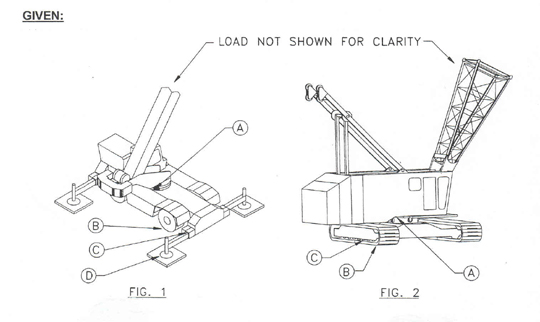

1. If soil stability is not a problem and the crane has been set up properly (blocked firm and level), what point on the crane do you watch in order to tell when tipping is starting to occur:

FIG. 1 A___ B___ C___ D___

FIG. 2 A___ B___ C___

2. When tipping starts to occur, what percentage of the crane's lifting capacity chart is the crane working at?

FIG. 1 _____________%

FIG. 2 _____________%

-

The answer to question 1, figure 1 is "C" and question 1, figure 2 is "C". When the truck crane starts to tip, the outrigger housing at point "C" will lift off the heavy outrigger(s) and float(s) and you can see daylight or space between them. When the crawler starts to tip, the track rollers at point "C" will lift off the heavy track pads and you can see daylight or space between them.

The answer to question 2, figure 1 is approximately 117 % of chart and question 2, figure 2 is approximately 133 %.

The answer to figure 1 is found by solving the ratio of 100 % of chart * 100 % of tipping/ 85 % of tipping = 117.65 % of chart. Figure 2 is found the same way except 75 % of tipping is used in the ratio instead of 85 %. The answers are approximate as the exact % of chart required to actually tip the crane over depends on the dynamics of the lift, wind, soil stability, etc.

The main purpose of this quiz is to show what percent of chart the cranes are actually working at if tipping is allowed to happen and the danger in doing so. Cranes should never be worked at capacities greater than 100 % of chart. At 100 % of the capacity chart, the cranes should still be down hard on the outriggers or track rollers with no signs of tipping. A lot of operators and riggers continue to load cranes until tipping occurs, rationalizing that they have (in the case of a crawler) "25 % in their pocket". In loading a crane to tipping, the operator is eating into the safety factor provided by the Manufacture and in some cases, working as few as 1 to 2 % outside the chart will change the rating from tipping to structural. Therefore, working a crane outside the lifting capacity chart is not only a bad rigging practice, it is a very dangerous practice. The crane manufactures, OSHA, ASME B30.5 forbids anyone working a crane outside of the capacity chart, to do so is an illegal practice.

Follow the link below to an article by Ron Kohner that explains the ramifications and dangers of working outside of the lifting capacity chart from a Crane Manufactures view point.

The secondary purpose of this quiz is to show the location on a crane where the signs of tipping first occur. Even though the lift must be planned to be within the lifting capacity chart, it is a good rigging practice to have someone watching the points of tipping on the counterweight side as well as watching the soil and load spreaders for settlement under the outrigger pads or crawler tracks on the load side. The lift should be stopped immediately if either signs of tipping or settlement are observed. Constructing a firm and level lift pad is one of the most important parts of a lift, but settlement can occur from unknowns such as poor soil compaction, underground water, underground voids, crushing of underground pipes, etc.

Ron Kohner's Article

Maximum Reach Enterprises